What is a surface resistance tester used for?

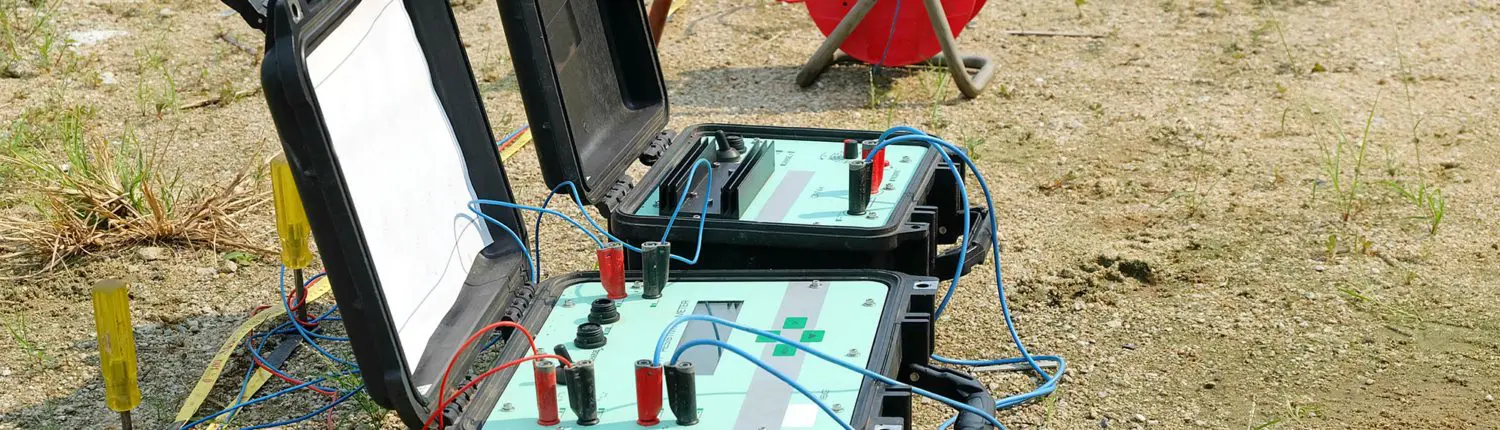

A surface resistance tester, also known as a surface resistivity meter, ESD tester, or anti-static surface tester, measures resistance to ground and surface resistivity. These instruments are commonly used in electrical manufacturing and assembly areas to prevent electrostatic discharge (ESD) that could damage sensitive electronic components.

How do surface resistance testers work?

Most surface resistance testers are compact, portable devices that provide readings using LED indicators and audible alarms. These testers verify whether measured resistance falls within safe limits, as outlined by EN 61340-5-1, ensuring compliance with electrostatic discharge control standards.

Why is calibration of surface resistance testers important?

Regular calibration ensures that ESD control measures remain effective, preventing static buildup that could damage integrated circuits, circuit boards, and other electronic components. Inaccurate testers could lead to unsafe working conditions and costly failures in sensitive equipment.

How often should a surface resistance tester be calibrated?

Leading manufacturers, such as Anti-Stat, recommend calibration every six months due to the safety-critical nature of these instruments. However, actual calibration frequency depends on individual quality control procedures. Calibrationhouse advises following manufacturer guidelines for optimal accuracy and compliance.

Can Calibrationhouse perform on-site calibration for surface resistance testers?

Yes, on-site calibration is available across the UK, ensuring minimal disruption for businesses that rely on surface resistance testers for ESD protection. Customers can also send their devices to our Durham-based laboratory for rapid turnaround calibration services.

For customers in the United States, surface resistance tester calibration is available at our Tampa facility, ensuring compliance with BSI ISO9001-certified standards.

Is UKAS-accredited calibration available for surface resistance testers?

Yes, Calibrationhouse provides UKAS-level certification for surface resistance testers, ensuring traceable and highly accurate calibrations that meet industry and safety standards. Additionally, calibration services at our Tampa facility in the United States adhere to BSI ISO9001-certified standards, ensuring compliance with global quality requirements.

How can I schedule calibration for my surface resistance tester?

To arrange calibration, contact Calibrationhouse via phone, email, or our online request form. Our team will guide you through the process and recommend the best calibration option based on your needs.