What is a digital indicator used for?

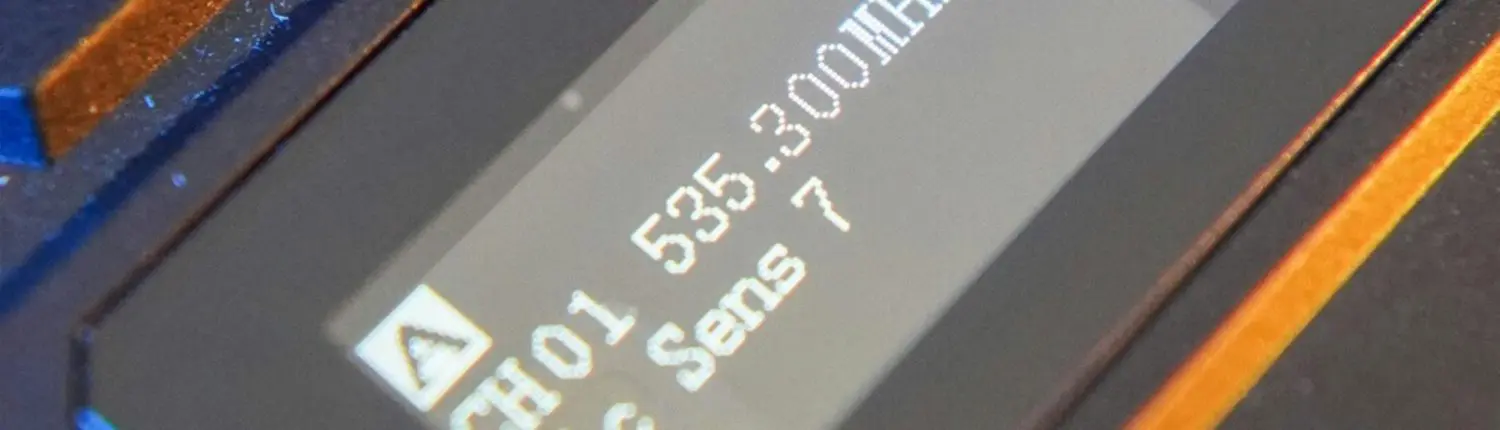

A digital indicator is a versatile measurement tool used in industries such as manufacturing, research, and development to measure parameters like current, voltage, temperature, and revolutions per minute (RPM). Some advanced models also provide control and signalling functions, making them an essential component of various monitoring systems.

How are digital indicators integrated into industrial systems?

Digital indicators can be portable devices, built into control panels, or mounted onto machinery. Many models are programmed and monitored in situ by technicians, while others feature remote communication capabilities, allowing for monitoring and adjustments via a PC or networked device.

Why is calibration of digital indicators important?

Regular calibration ensures digital indicators provide accurate and reliable measurements, preventing incorrect readings that could impact production, research outcomes, or safety compliance. It is essential to consider both the measured parameters and system setup when performing calibration.

How much experience does Calibrationhouse have with digital indicator calibration?

Calibrationhouse has over 20 years of experience calibrating digital indicators across various industries and applications. Our engineers understand the complexities of these systems and provide tailored calibration services to meet specific requirements.

How can I arrange calibration for my digital indicator?

To schedule calibration, contact Calibrationhouse via phone, email, or our online request form. Our team will assess your requirements and advise on the best calibration solution, whether on-site or at our laboratory.